Radar substance level gauge

Category: Level transmitter

Product Details

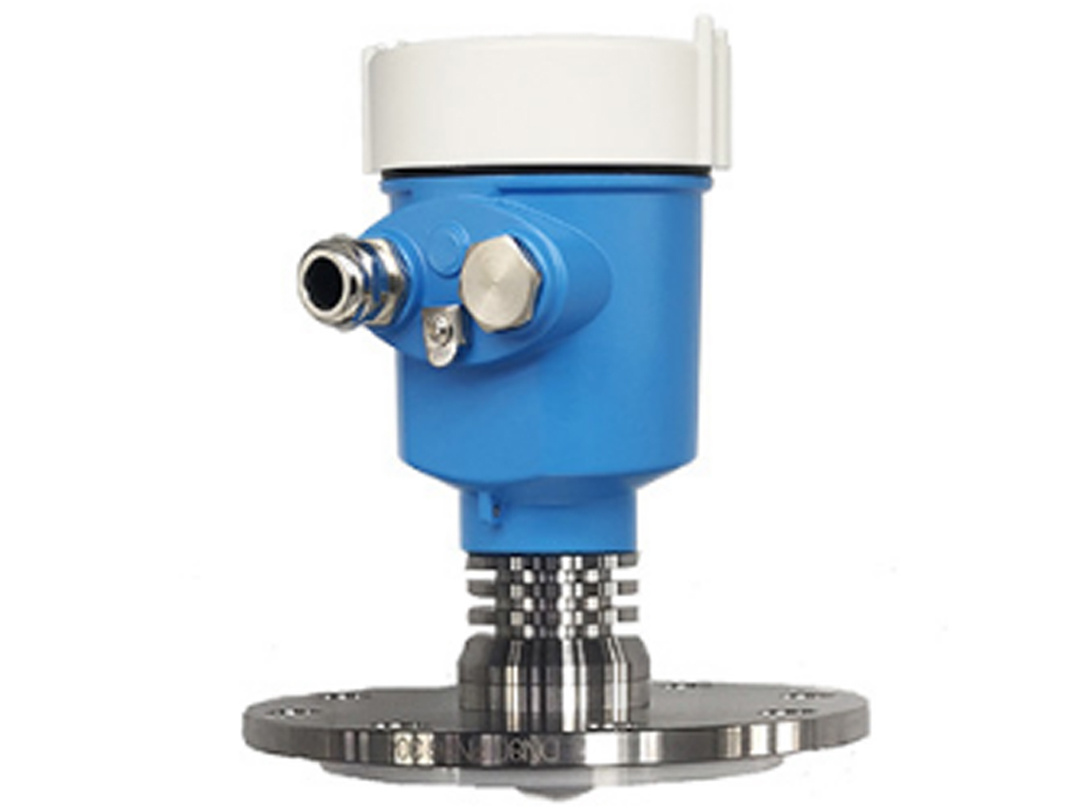

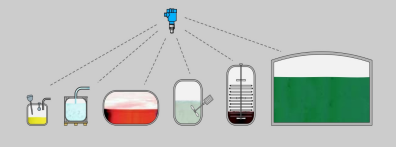

Radar sensors for all liquid measurement applications

Radar level measuring instrument with 80GHz frequency. Radar beams have unique focusing capabilities. Compared with 26G or 6G radar, it has the characteristics of higher frequency, shorter wavelength, smaller beam angle and more concentrated energy. Even in containers with built-in components, such as heating coils or stirring devices, the sensor provides reliable measurement results, and the attachment on the inner wall of the container does not affect the accurate measurement results.

The larger the dynamic range of a radar sensor, the wider its application range and the higher its measurement reliability. In this regard, 80GHz occupies a leading position in the market. Compared to radar sensors hitherto, it is clearly better able to measure poorly reflective media. It can measure the liquid level even when it is very close to the bottom of the container. Even in the presence of foam, extreme vibrations on the surface of the medium, the presence of condensate or the presence of attachments on the antenna, it can be measured safely and reliably.

Having the smallest antenna in its type is a great advantage when used in small tanks or process vessels. Therefore, it can be used in different industrial fields and more different occasions.

Frequency | 80GHz/FMCW(W-band) | 26GHz/Pulse(K-band) |

Measurement range | Liquid 0-30m/Solid 120m | Liquid 0-30m/Solid 70m |

Wavelength | 3mm | 10mm |

beam angle | 3°~6° | 4°~18° |

Measurement accuracy | ±2mm~±5mm | ±3mm~±15mm |

blind area | 0.2-0.5M | 0.5M |

Process Connection | Flange or G1 1/2, 3/4 thread (NPT) | Flange or G1 1/2 thread (NPT) |

Features | The antenna size is extremely small, the direction is better, the material surface reflection signal is stronger, suitable for strong dust occasions, suitable for small tanks, loose installation environment. | Compared with the 6G low-frequency radar antenna, the antenna is small in size and high in precision, and the antenna tries to probe out of the tank. |

Additional Options | Bluetooth debugging function |

|

80GHz FM Radar Level Meter

Principle

The 80G radar level gauge adopts frequency modulated continuous wave (FMCW) technology. The antenna emits a Gauton's FM radar signal, and the frequency of the radar signal increases linearly. The transmitted radar signal is received by the same antenna after being reflected by the measured medium.

At the same time, the frequency difference between the transmitting signal frequency and the receiving signal frequency is proportional to the measured distance. The frequency difference signal is collected, and the spectrum of the reflected echo is obtained by fast Fourier transform (FFT), and the distance to be measured is calculated.

Features

Compared with 26G or 6G radar, 80G radar has the characteristics of higher frequency, shorter wavelength, smaller beam angle and more concentrated energy. With the application of FMCW technology, 80G radar has the following characteristics:

- Large range, small blind area

- The beam angle is small, the antenna size is small, and it is easy to install. Small impact of obstacles due to tank nozzle size

- High measurement accuracy, strong anti-interference ability and high reliability.

Application

Refitting on existing equipment is simple and does not require modification.

Thread type, flange type interface and sanitary sterile interface suitable for different industrial fields

1. Parameter introduction

No. | Application | Measurement range | Process Connection | Process temperature | Process pressure | Accuracy | Antenna material | Frequency | Explosion-proof grade | Protection level | Output signal | Field Display | Power supply | four-wire system |

HDLRD810 | Liquid | 0~30m/0~120m | G ¾ thread | (-40~90)℃ | (-0.1~0.1)MPa | ±2mm | lens antenna/PP/PTFE | 80GHz | Exia IICT6/Exd IICT6 | shell aluminum shell IP67/plastic shell IP65 | (4~20)mA/HART/RS485(Modbus) | Dot matrix liquid crystal, can display curve (standard) | Two-wire system (DC24V) | (DC24V or AC220V) |

HDLRD811 | Corrosive liquid | 0~30m/0~120m | Thread | (-40~90)℃ | (-0.1~0.1)MPa | ±2mm | lens antenna/PP/PTFE | 80GHz | Exia IICT6/Exd IICT6 | shell aluminum shell IP67/plastic shell IP65 | (4~20)mA/HART/RS485(Modbus) | Dot matrix liquid crystal, can display curve (standard) | Two-wire system (DC24V) | (DC24V or AC220V) |

HDLRD812 | Liquid | 0~30m | Flange | (-40~150)℃/(-40~200)℃ | (-0.1 ~ 0.1)MPa/(-0.1 ~ 2.5)MPa | ±2mm | lens antenna/stainless steel PTFE | 80GHz | Exia IICT6/Exd IICT6 | shell aluminum shell IP67/plastic shell IP65 | (4~20)mA/HART/RS485(Modbus) | Dot matrix liquid crystal, can display curve (standard) | Two-wire system (DC24V) | (DC24V or AC220V) |

HDLRD813 | Liquid | 0~10m/0~30m/0~120m | Thread | (-40~120)℃/(-40~200)℃ | (-0.1 ~ 0.1)MPa/(-0.1 ~ 2.5)MPa | ±2mm | lens antenna/stainless steel PTFE | 80GHz | Exia IICT6/Exd IICT6 | shell aluminum shell IP67/plastic shell IP65 | (4~20)mA/HART/RS485(Modbus) | Dot matrix liquid crystal, can display curve (standard) | Two-wire system (DC24V) | (DC24V or AC220V) |

HDLRD814 | Solid/Liquid | 0~120m | Flange | (-40~110)℃/(-40~130)℃/ | (-0.1~0.1)MPa | ±5mm | lens antenna/stainless steel PTFE | 80GHz | Exia IICT6/Exd IICT6 | shell aluminum shell IP67/plastic shell IP65 | (4~20)mA/HART/RS485(Modbus) | Dot matrix liquid crystal, can display curve (standard) | Two-wire system (DC24V) | (DC24V or AC220V) |

HDLRD311 | Liquid, solid powder | 10 m | Thread/Flange (optional) | -40~150 ℃ (standard type)-40~250 ℃ (high temperature type) | -0.1~2.0MPa | ±3mm |

| 100MHz~1.8GHz | ExiaⅡC T6 Ga | IP 67 | 4~20mA/HART |

| Two-wire system (DC24V) | (DC24V/AC220V) |

HDLRD312 | Liquid | 6 m | Thread/Flange (optional) | -40~150 ℃ (standard type)-40~250 ℃ (high temperature type) | -0.1~2MPa | ±3mm |

|

100MHz~1.8GHz

| ExiaⅡC T6 Ga | IP 67 | 4~20mA/HART |

| Two-wire system (DC24V) | (DC24V/AC220V) |

HDLRD313 | Liquid, solid powder | 20 meters | Flange (optional) | -40~150 ℃ (standard type) -40~250 ℃ (high temperature type) | -0.1~2MPa | ±3mm |

| 100MHz~1.8GHz | ExiaⅡC T6 Ga | IP 67 | 4~20mA/HART |

| Two-wire system (DC24V) | (DC24V/AC220V) |

HDLRD314 | Liquid | 6 m | Flange (optional) | -200~400 ℃ | -0.1~40MPa | ±3mm |

| 100MHz~1.8GHz | ExiaⅡC T6 Ga | IP 67 | 4~20mA/HART |

| Two-wire system (DC24V) | (DC24V/AC220V) |

Unit Parameters

4. Instrument selection

Unit | Parameters | |

Explosion-proof requirements | P Standard type (non-explosion-proof) | |

I | Intra-safe (Exia IIC T6 Ga) | |

D | Flameproof (Exd IIC T6 Ga) | |

Antenna type/material/temperature | A | G1% "Teflon Sealed Lens Antenna |

B | G1% "stainless steel hermetically sealed lens antenna | |

C | G3% "fully sealed lens antenna | |

D | G3M "Fully Sealed Gimbal Lens Antenna | |

Y | Special customization | |

Process Connection | G | Thread G1% "A |

N | Thread 1% "NPT | |

B | Flange DN50/stainless steel 304 | |

C | Flange DN80/stainless steel 304 | |

D | Flange DN100/stainless steel 304 | |

Y | Special customization | |

Sealing process temperature | V | Viton/(-40~150)℃ |

B | Kalrez/(-40 ~ 250)℃ | |

Electronic Unit | 6 | (4~20)mA/24VDC two-wire system |

7 | (4~20)mA/24V DC/HART two-wire system | |

8 | (4~20)mA/220V AC four-wire system | |

9 | RS485/Modbus | |

R | Special customization | |

Enclosure/Degree of Protection | L | Aluminium/IP 67 |

G | Stainless steel 304/IP 67 | |

Cable Interface | M | M20x1.5 |

N | %"NPT | |

Field Display | U | Belt |

X | without | |

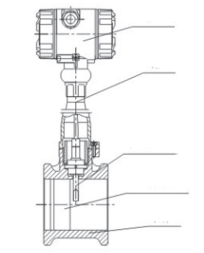

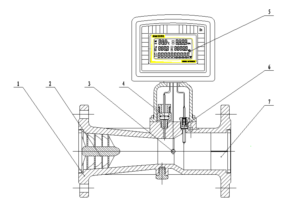

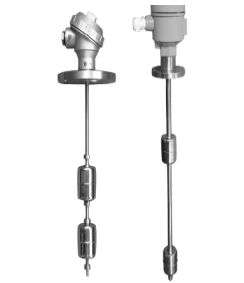

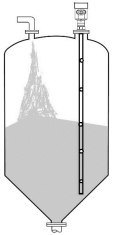

guided wave radar level meter

Principle

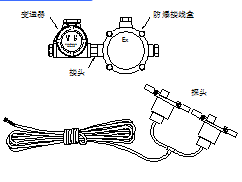

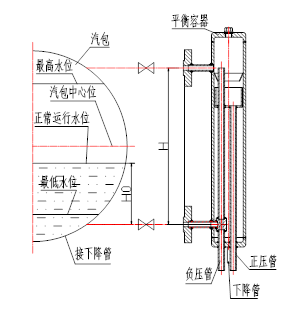

Guided wave radar level gauge is a ranging system based on the principle of time travel. The instrument probe sends out a 1GHz micro-power electromagnetic wave signal along the detection component (probe rod or detection cable) to propagate at the speed of light. When the battery wave contacts the surface of the measured substance, the electromagnetic wave is reflected back due to the sudden change of dielectric constant. The reflected electromagnetic wave propagates along the probe assembly and returns to the meter probe. The time interval between the emission and reception of the electromagnetic wave is proportional to the distance from the instrument probe to the measured medium, so that the distance from the instrument probe to the surface of the measured medium can be calculated.

Input

The reflected pulse signal is transmitted to the electronic circuit part of the instrument along the cable or rod probe, and the microprocessor processes the signal to identify the echo generated by the microwave pulse on the surface of the material. The correct echo signal recognition is completed by intelligent software, and the distance D from the surface of the material is proportional to the time travel T of the pulse:

D = C×T/2 where C is the speed of light

Since the distance E of the empty tank is known, the level L is: L = E-D

Output

By inputting empty tank height E(= zero point), full tank height F(= full scale) and some application parameters, the application parameters will automatically adapt the instrument to the measurement environment. Corresponds to 4... 20mA output.

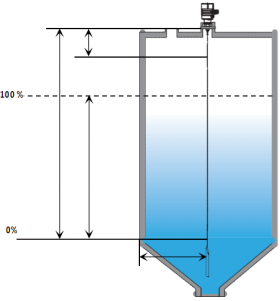

Measurement range

F-measurement range

E ---- empty tank distance

B- --- Top blind area

H ---- minimum distance from the probe to the tank wall

The top blind area is between the highest material level of the material and the measurement reference point.

The minimum distance.

The bottom blind area refers to the area near the bottom of the cable that cannot be accurately measured.

A distance.

Between the top blind area and the bottom blind area is the effective measurement distance.

Note: Only when the material is between the top blind area and the bottom blind area, can the reliable measurement of the level in the tank be guaranteed.

1. Instrument parameters

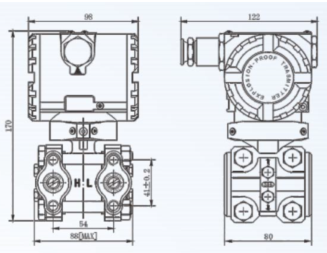

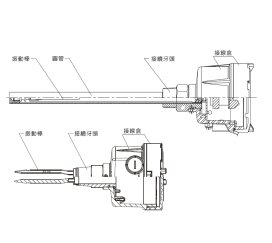

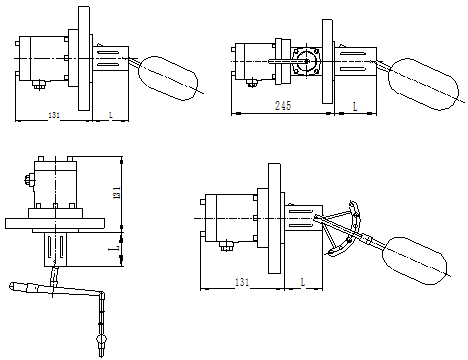

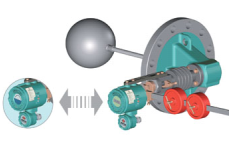

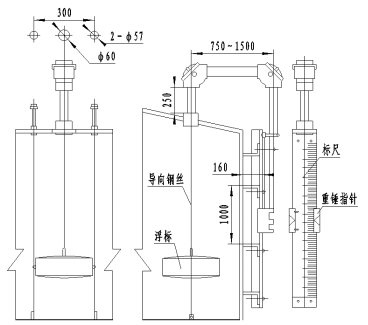

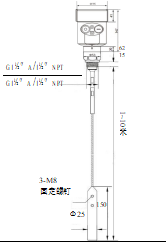

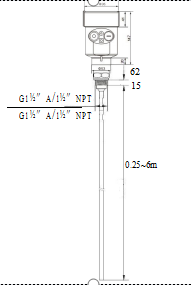

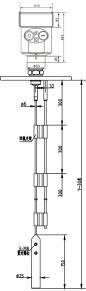

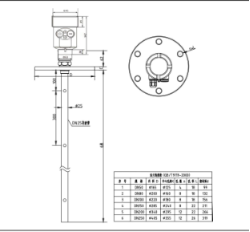

2. Overall dimension

3. Installation requirements

4. Instrument selection

Unit | Parameter note: away from the discharge port | |

Explosion-proof requirements |

| P Standard type (non-explosion-proof) |

| I Intra-safe (Exia IIC T6 Ga) | |

| D Flameproof (Exd IIC T6 Ga) | |

Antenna type/material/temperature |

| A cable probe stainless steel 304 |

| Y Special Customization | |

Process Connection |

| G thread G1% "A |

| N thread 1% "NPT | |

| B flange DN50/stainless steel 304 | |

| C flange DN80/stainless steel 304 | |

| D flange DN100/stainless steel 304 | |

| E flange DN125/stainless steel 304 | |

| F flange DN150/stainless steel 304 | |

| Y Special Customization | |

Sealing process temperature |

| V Viton/(-40 ~ 150)℃ |

| B Kalrez/(-40~250)℃ | |

Electronic Unit |

| 6(4~20)mA/24V DC two-wire system |

7 | (4~20)mA/24V DC/HART two-wire system | |

| 8 (4~20)mA/220V AC four-wire system | |

| R Special Customization | |

Enclosure/Degree of Protection |

| l Aluminum/IP 67 |

| G stainless steel 304/IP 67 | |

Cable Interface |

| M M20x1.5 |

| N %” NPT | |

Field Display |

| U band |

| X | |

1. Instrument parameters

2. Overall dimension

3. Installation requirements

4. Instrument selection

Unit | Parameters | |

Explosion-proof requirements | P | Standard (non-explosion-proof) |

I | Intra-safe (Exia IIC T6 Ga) | |

| D Flameproof (Exd IIC T6 Ga) | |

Antenna type/material/temperature |

| A- bar probe stainless steel 304 |

| Y Special Customization | |

Process Connection |

| G thread G1% "A |

| N thread 1% "NPT | |

B | Flange DN50/stainless steel 304 | |

C | Flange DN80/stainless steel 304 | |

D | Flange DN100/stainless steel 304 | |

| E flange DN125/stainless steel 304 | |

F | Flange DN150/stainless steel 304 | |

| Y Special Customization | |

Sealing process temperature | V | Viton/ (-40~150)℃ |

B | Kalrez/(-40 ~ 250)℃ | |

Electronic Unit | 6 | (4~20)mA/24V DC two-wire system |

7 | (4~20)mA/24V DC/HART two-wire system | |

8 | (4~20)mA/220V AC four-wire system | |

R | Special customization | |

Enclosure/Degree of Protection | L | Aluminium/IP 67 |

G | Stainless steel 304/IP 67 | |

Cable Interface |

| M M20x1.5 |

| N %" NPT | |

Field Display |

| U band |

X | without | |

1. Instrument parameters

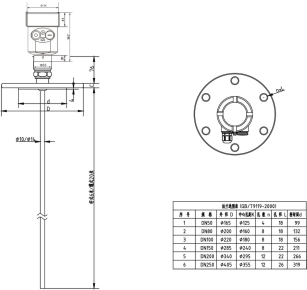

2. Overall dimension

3. Installation requirements

4. Instrument selection

Unit | Parameters | |

Explosion-proof requirements | P Standard type (non-explosion-proof) | |

I | Intra-safe (Exia IIC T6 Ga) | |

D | Flameproof (Exd IIC T6 Ga) | |

Antenna type/material/temperature | A | Dual Cable Probe Stainless Steel 304 |

Y | Special customization | |

Process Connection | C | Flange DN80/stainless steel 304 |

D | Flange DN100/stainless steel 304 | |

E | Flange DN125/stainless steel 304 | |

F | Flange DN150/stainless steel 304 | |

Y | Special customization | |

Sealing process temperature | V | Viton/ (-40~150)℃ |

B | Kalrez/(-40 ~ 250)℃ | |

Electronic Unit | 6 | (4~20)mA/24V DC two-wire system |

7 | (4~20)mA/24V DC/HART two-wire system | |

8 | (4~20)mA/220V AC four-wire system | |

R | Special customization | |

Enclosure/Degree of Protection | L | Aluminium/IP 67 |

G | Stainless steel 304/IP 67 | |

Cable Interface | M | M20x1.5 |

N | %" NPT | |

Field Display | U | Belt |

X | without | |

1. Instrument parameters

2. Overall dimension

3. Installation requirements

4. Instrument selection

Unit | Parameters | |

Explosion-proof requirements | P | Standard (non-explosion-proof) |

I | Intra-safe (Exia IIC T6 Ga) | |

D | Flameproof (Exd IIC T6 Ga) | |

Antenna type/material/temperature | A | Cable probe stainless steel 304 |

B | Rod probe stainless steel 304 | |

Y | Special customization | |

Process Connection | B | Flange DN50/stainless steel 304 |

C | Flange DN80/stainless steel 304 | |

D | Flange DN100/stainless steel 304 | |

E | Flange DN125/stainless steel 304 | |

F | Flange DN150/stainless steel 304 | |

Y | Special customization | |

Sealing process temperature | V | Viton/ (-40~150)℃ |

B | Kalrez/(-40 ~ 250)℃ | |

Electronic Unit | 6 | (4~20)mA/24V DC two-wire system |

7 | (4~20)mA/24V DC/HART two-wire system | |

8 | (4~20)mA/220V AC four-wire system | |

R | Special customization | |

Enclosure/Degree of Protection | L | Aluminium/IP 67 |

G | Stainless steel 304/IP 67 | |

Cable Interface | M | M20x1.5 |

N | %” NPT | |

Field Display | U | Belt |

X | without | |

1. Instrument parameters

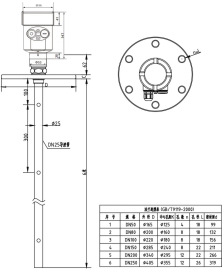

2. Overall dimension

3. Installation requirements

4. Instrument selection

Unit | Parameters | |

Explosion-proof requirements | P Standard type (non-explosion-proof) | |

I | Intra-safe (Exia IIC T6 Ga) | |

D | Flameproof (Exd IIC T6 Ga) | |

Antenna type/material/temperature | A | Rod probe stainless steel 304 |

Y | Special customization | |

Process Connection | G thread G1%"A | |

N | Thread 1% "NPT | |

B | Flange DN50/stainless steel 304 | |

C | Flange DN80/stainless steel 304 | |

D | Flange DN100/stainless steel 304 | |

E | Flange DN125/stainless steel 304 | |

F | Flange DN150/stainless steel 304 | |

Y | Special customization | |

Sealing process temperature | V | Viton/(-40~150)℃ |

B | Kalrez/ (-40 ~ 250)℃ | |

Electronic Unit | 6 | (4~20)mA/24V DC two-wire system |

7 | (4~20)mA/24V DC/HART two-wire system | |

8 | (4~20)mA/220V AC four-wire system | |

R | Special customization | |

Enclosure/Degree of Protection | L | Aluminium/IP 67 |

G | Stainless steel 304/IP 67 | |

Cable Interface | M | M20x1.5 |

N | %” NPT | |

Field Display | U | Belt |

X | without | |

1. Instrument parameters

2. Overall dimension

3. Installation requirements

4. Instrument selection

Unit | Parameters | |

Explosion-proof requirements | P Standard type (non-explosion-proof) | |

I | Intra-safe (Exia IIC T6 Ga) | |

D | Flameproof (Exd IIC T6 Ga) | |

Antenna type/material/temperature | A | Rod probe stainless steel 304 |

Y | Special customization | |

Process Connection | G thread G1%"A | |

N | Thread 1% "NPT | |

B | Flange DN50/stainless steel 304 | |

C | Flange DN80/stainless steel 304 | |

D | Flange DN100/stainless steel 304 | |

E | Flange DN125/stainless steel 304 | |

F | Flange DN150/stainless steel 304 | |

Y | Special customization | |

Sealing process temperature | V | Viton/(-40~150)℃ |

B | Kalrez/ (-40 ~ 250)℃ | |

Electronic Unit | 6 | (4~20)mA/24V DC two-wire system |

7 | (4~20)mA/24V DC/HART two-wire system | |

8 | (4~20)mA/220V AC four-wire system | |

R | Special customization | |

Enclosure/Degree of Protection | L | Aluminium/IP 67 |

G | Stainless steel 304/IP 67 | |

Cable Interface | M | M20x1.5 |

N | %” NPT | |

Field Display | U | Belt |

X | without | |

Radar Level Gauge InstructionsRadar material level gauge manual (1).doc

The company's mission

Rely on science and technology for development, continue to provide users with satisfactory products, is the company's constant pursuit. Customer is the vitality of the enterprise, customer satisfaction is the focus of the company. By continuously improving the quality of products and services, we provide customers with high-quality, safe and reliable products and enthusiastic, professional and comprehensive services to obtain customer satisfaction. Create a series of products such as "Hydron" brand level gauges, water level gauges, level gauges, high-temperature furnace monitors, etc., to improve product quality and corporate reputation, and become the priority selection of China National Petroleum Corporation, China National Petroleum Corporation, Wuhan Iron and Steel, Wuhan Ethylene High-quality products, create a well-known brand of Chinese instruments, and compete in the international market.

The company's values

Continuously improve product quality, improve product varieties, and create a well-known brand of national instruments with a pragmatic attitude, pioneering spirit, and innovative consciousness. To provide our customers with first-class products and quality services. In today's world economic integration has become a trend, only across the country, to the international market, in order to obtain greater space for development, the development of national instrument well-known brands.

The company's values

People-oriented: the company takes care of everyone as an important principle of work, trust and love every employee;

Customer first: the company is committed to meet the needs of customers, provide first-class service, pay attention to customer satisfaction;

Love and dedication: employees love their posts, carefully do their work, create wealth for the society at the same time, create a happy life for themselves;

Excellence and innovation: the pursuit of excellence is the company's ideal, innovation is the soul of the company, only the pursuit of excellence, continuous innovation, in order to make the company prosperous and constantly create brilliant.

Humanistic concept

Heidelon-the sea is inclusive of all rivers, the dragon is running all things, and the dragon is in the world.

Keyword:

Radar substance level gauge